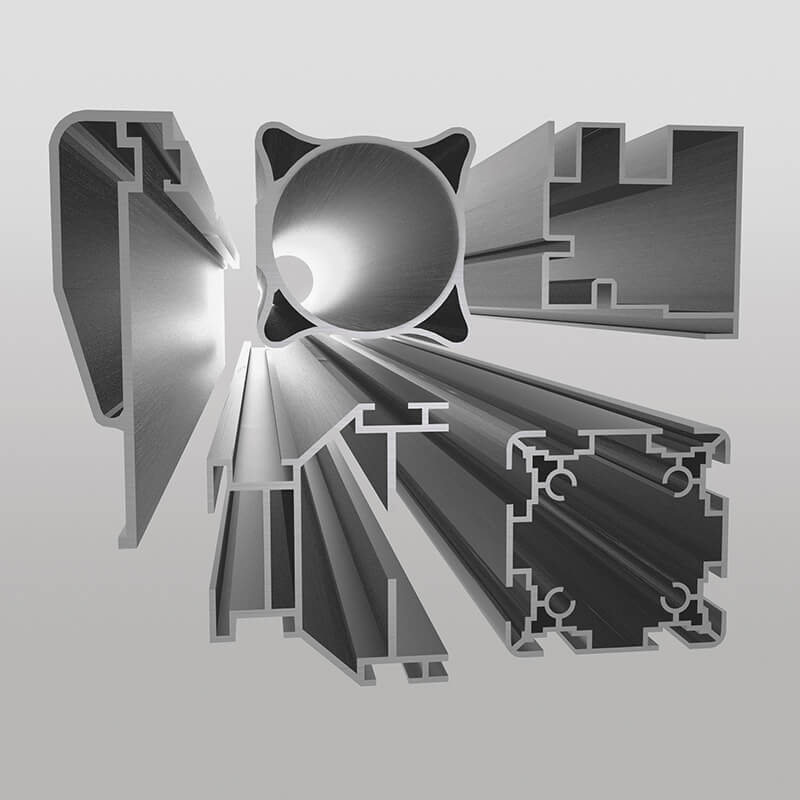

Friction stir welding

La tecnologia FSW che abbatte ogni limite: non solo macchinari, ma soluzioni per progettare il futuro della tua impresa.

Perché sceglierci

Un’azienda solida, il miglior partner per l’automotive e l’industria del futuro.

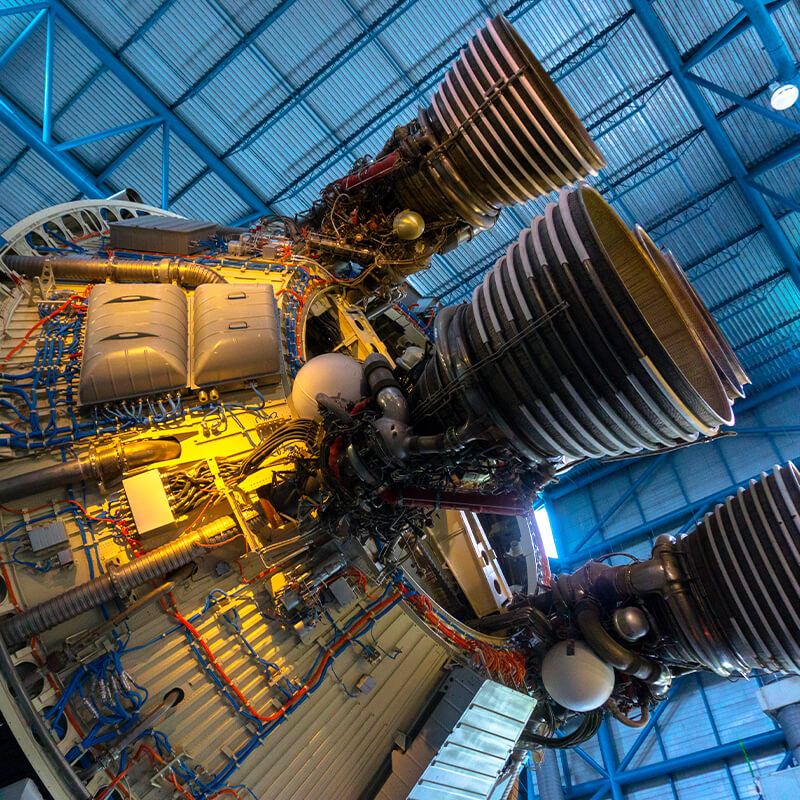

Settori di utilizzo

Per terra, per mare, nello spazio: supportiamo le industrie che innovano e salvaguardano il nostro pianeta.

Realizza con noi il tuo progetto

Compila il form e carica un’immagine o il 3D del progetto che vuoi realizzare. Se hai bisogno di aiuto scrivilo nel messaggio, siamo qui per supportarti in ogni fase.